- …

- …

OUR STORY

A Commitment to Quality and Sustainability

At XDD TEXTILE, we control the entire production process from raw materials to finished garments.

With our fully integrated production system, we can ensure the highest standards of quality,

traceability and sustainability - from seed to shelf.

Environmental stewardship is at the core of our company.

We have implemented innovative recycling technologies that allow us to achieve

recycling rates of up to 80% today, with a goal of 100% by 2025.

Our Reverse Osmosis System recover up to 85% of our water usage, saving millions of liters annually.

For some products, we have created a Closed-Loop System

where we reutilize our own denim waste, minimizing material waste.

Our expertise lies in creating beautifully rich and authentic fabrics with vintage appeal.

The natural imperfections and variations in our fabrics - combined with our extensive color palette - lend garments an irresistible broken-in, worn-in feel right from the start.

This "Vintage Friendly" philosophy allows our customers to create Shrink-to-Fit styles with effortless aesthetic.

At XDD TEXTILE, we take pride in high craftsmanship,

proven sustainability practices and our unique vintage - inspired fabrications - all driven by our commitment to making quality garments that stand the test of time.

SPINNING & DENIM FACILITIES

1st SPINNING MILL

Launched in 2014

15 hectares

Capacity:

6000 Tons of yarn per month

-220,000 ring spindles, 3500 tons monthly

-9 OE units, 1500 tons monthly

-100% Cotton compact combed yarn /

Siro-compact combed yarn from 6s-120s for knitting and weaving

-OE5.5 - OE20S

DENIM MILL

Launched in 2019

15 hectares

Capacity:

4 Millions yds monthly

-Dyeing ( 2 Slasher Dye & 2 Rope Dye)

-330 Picanol rapier looms

-50 Traditional shuttle weaving machine

Selvedge Capacity : 150,000 yds monthly

Premium Quality From Fiber To Fabric

A STABLE COTTON SUPPLY

100% BCI - certified cotton with U.S. Cotton Trust Protocol and Higg Index, traceable and transparent.

Under the current global cotton shortage situation,

can ensure that we have a stock preserve over 20000 TONS amount

ready for any order we receive to meet your demand.

LABORATORY CERTIFICATION

BRAND CERTIFICATED laboratory

SUSTAINABILITY

XDD DENIM it has always been committed to innovating products according to market trends

and maintaining the concept of sustainability. To provide marketable denim for the industry.

WATER RECYCLING

Reverse Osmosis System

Our Reverse Osmosis (RO) System is designed to deliver exceptional performance,

achieving an impressive 85% efficiency.

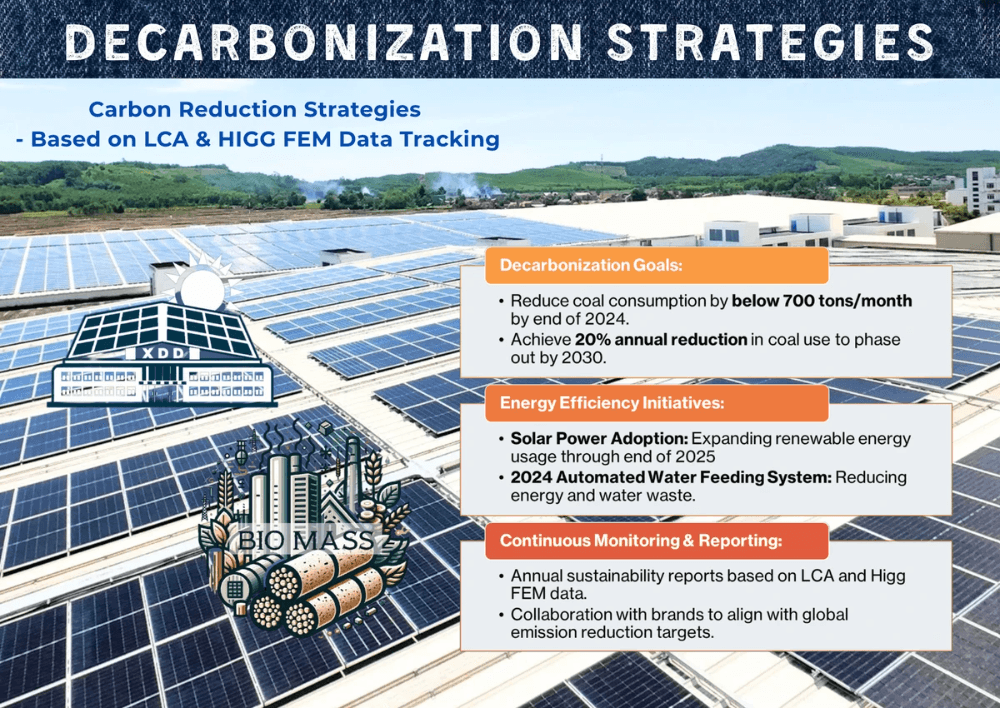

DECARBONIZATION STRATEGIES

Renew energy CARBON BET ZERO

Energy Efficiency / Renewable Energy Transition / Process Optimization

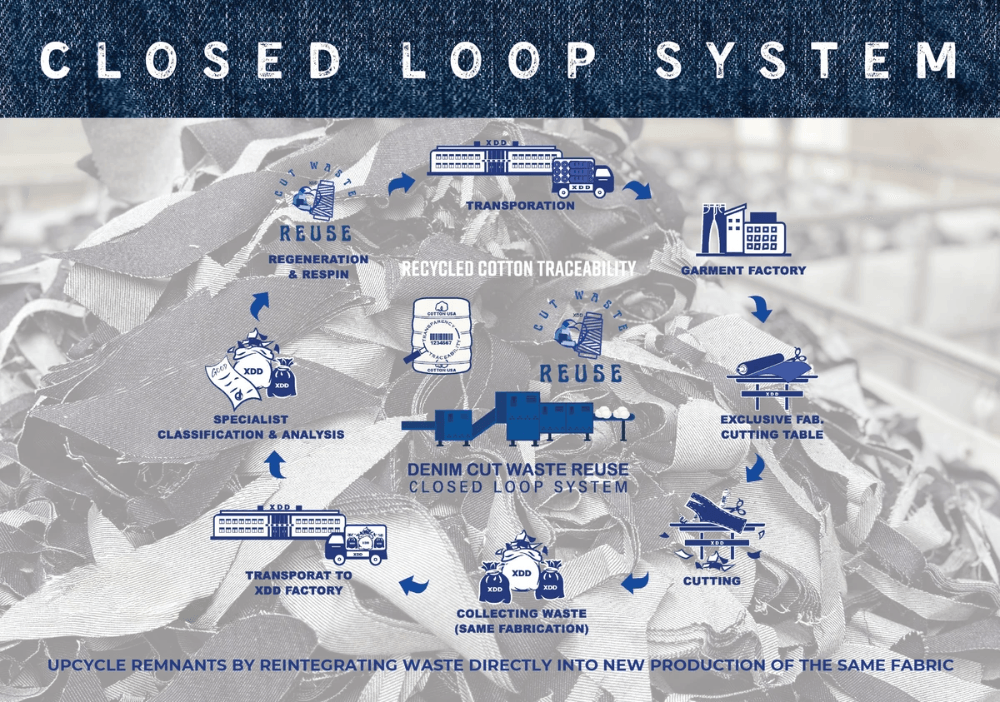

DENIM CUT WASTE REUSE

Closed Loop System

Regenerates 10 to 15% denim waste of monthly output from pre consuming ends including cotton, yarn and fabric cut waste.

Reproduce yarn and apply similar fabric products to assure quality consistency and tracebility.

UNIQUE

Our Unique Vintage Appeal

Vintage friendly and Laser Friendly fabrics are at the heart of what sets us apart from other mills.

The ability to easily create vintage aesthetics right from fabric development,

combined with our proven laser suitability,

empowers your brands and designers to unlock creative possibilities at the cutting edge of denim innovation.

We offer an easy route to creating truly authentic-looking vintage jeans.

Starting from the unfaded indigo of our denim,

even a simple rinse wash produces beautifully marbled effects and subtle gradients that mimic years of wear.

In addition to our innate vintage appeal, our fabrics achieve the highest standards of laser fitness. Whether medium or dark indigo,

XDD denim consistently scores "green" in blue wrap tests, ensuring optimal performance in laser finishing techniques.

Selvedge Denim

Experience the timeless appeal of premium craftsmanship with our Selvedge Denim collection, proudly crafted by one of the limited selvedge denim suppliers in Vietnam, with production capacity of 150,000 yards per month.

Our selvedge denim embodies exceptional quality and captures the essence of vintage aesthetics, appealing to connoisseurs of classic and authentic denim.

Recognized and praised by renowned Japanese denim brands, partnerships have bolstered sales in the competitive Japanese market, a testament to our commitment to excellence.

As we continue to innovate, our focus remains on elevating our selvedge denim to reflect an unmatched blend of premium quality and classic character, delivering denim that stands the test of time.

Body Embrace

Denim Collection

Discover the perfect harmony of comfort, style, and innovation with our

Body Embrace denim collection, thoughtfully designed for women who seek both sophistication and ease.

Each piece in this collection is crafted with the most suitable fabric weight and optimal elongation, ensuring a flawless fit that moves with you.

From classic cuts to trendy silhouettes, Body Embrace combines cutting-edge fabric technology with modern aesthetics, offering denim that sculpts and enhances the natural shape while maintaining unparalleled comfort.

Every detail reflects our commitment to innovation, from the selection of best fabrics to the stylish finishes that elevate each design. Whether you're dressing up or down, Body Embrace redefines denim to suit your lifestyle and individuality.

Soufflé Denim Collection

Introducing the Souffle Denim collection, a breakthrough in denim innovation that combines luxurious softness with sustainability.

Crafted using low-twist yarn technology, this fabric achieves an ultra-fluffy, voluminous hand feel without compromising tensile strength.

Designed with versatility in mind, Souffle Denim can be applied to both warp and weft yarns, maximizing comfort and creating a premium texture. Made from 100% cotton, it aligns with a sustainable perspective while delivering an extravagantly soft drape effect that retains a vintage aesthetic.

Perfectly suited for new and trending silhouettes, this collection offers exceptional drapability, hand feel, and all-day wearing comfort, making it a gender-inclusive choice for modern denim lovers.

NEWS

Featured in the Press

“XDD textiles has recently set up a denim mill in Vietnam . Our readers would like to know more about XDD and its background, growth etc.”

a post in @Denimsandjeans

This milestone marks the company’s first attendance at the Denimsandjeans event. The two-day event promises to offer insight into new trends, best practices, and Xdd’s commitment towards developing technologies that promote sustainability. We spoke to the Director of XDD Vietnam Mr Man Ng to know more about the company’s operations and vision .

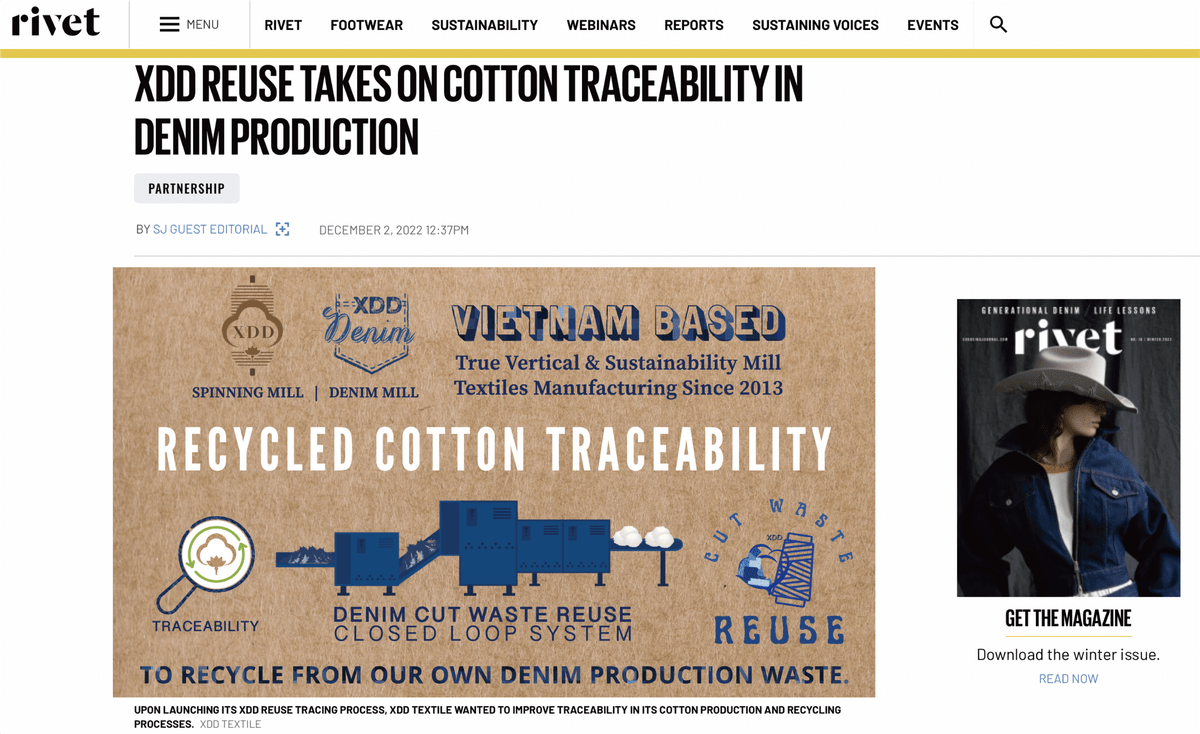

“XDD REUSE TAKES ON COTTON TRACEABILITY IN DENIM PRODUCTION”

a post in @rivetandjeans@sourcingjournal

XDD Textile takes pre-consumer waste collected from the mill’s partner garment factory to be regenerated and respun into good-as-new cotton. This recycled cotton is derived from the cuttable wastage from XDD’s own fabric, which is why the cotton can be traceable.

"XDD STRENGTHENS COTTON RECYCLING TO CUT TEXTILE WASTE"

a post in @rivetandjeans@sourcingjournal

To fortify its spinning and denim manufacturing operation, Vietnam-based XDD Textile has built a recycling process designed to divert more products from landfills, which would help alleviate the estimated 25 billion pounds in annual textile waste produced, according to the Council for Textile Recycling.

''XDD DEBUTS CLOSED-LOOP SYSTEM TO BRING DENIM WASTE BACK TO LIFE''

a post in @rivetandjeans@sourcingjournal

XDD TEXTILE , a vertically integrated fabric producer that operates four mills across Vietnam, is making new strides in circularity with its new CLOSED-LOOP SYSTEM using the XDD Sewage Recycle Process.

The main purpose of the closed-loop system is to reuse and recycle waste, which is vital to the company since Vietnam has banned the import of certain waste materials into the country.

''XDD DEBUTS 2ND SKIN ECO-FRIENDLY STRETCH DENIM FOR ONE-SIZE FIT''

a post in @rivetandjeans@sourcingjournal

XDD has developed a new denim fabric called 2nd Skin, which is manufactured to provide jeans wearers with a sustainable ultra-stretch feel with excellent recovery capabilities.

2nd Skin is XDD’s newest '' One Size Fit'' collection that can fit a range of differently sized people, as the jeans may be snugger on larger frames and baggier on smaller bodies.

''XDD TEXTILE DEBUTS CLOSED-LOOP SYSTEM, UPCOMING SPINNING MILL''

a post in @rivetandjeans@sourcingjournal

XDD Textile, a vertically integrated fabric producer based in Hong Kong, is making strides in circularity. The company launched a closed-loop system using the XDD Sewage Recycle Process.

''XDD PREVIEWS 7 COLLECTIONS AHEAD OF KINGPINS AMSTERDAM''

a post in @rivetandjeans@sourcingjournal

XDD will be launching seven new collections on the show floor at Kingpins in Amsterdam, taking place on April 20-21, 2022. Each collection will be defined by a “story” with its own unique characteristics.

“XDD DENIM TAKES ‘VINTAGE-FRIENDLY’ APPROACH TO MANUFACTURING JEANS”

a post in @rivetandjeans@sourcingjournal

The purpose of vintage-friendly products and Sustainability from XDD.

At XDD Denim, a division of XDD Textiles, it’s all about developing sustainable product, cutting waste from the manufacturing process and giving wearers the “vintage” feel that is trendy for all seasons.

''XDD'S NEW FABRIC MAKES USE OF TEXTILE WASTE''

a post in @rivetandjeans @sourcingjournal

Eco with “5 in 1 concept,” Happy to share our solution for the local textile industry’s waste.

ECOLOGY fabric is able to improve our sustainable levels.

“HOW VIETNAM MILL XDD DENIM IS TACKLING WASTE”

a post in @carvedinblue

For Vietnam’s XDD Denim, recycling is a pivotal part of its sustainability strategy. Water gets processed for reuse, and fabric waste gets turned into new textiles. Ours international plans is to use circular TENCEL™️ x REFIBRA™️ fibers.

EXHIBITIONS

All around the world

Denims and Jeans Vietnam - HO CHI MINH, VIETNAM - 25-26 JUNE 2025

Tokyo Textile Scope - TOKYO - 14-16 May 2025

KINGPINS SHOW - AMSTERDAM - 16,17 April 2025

KINGPINS SHOW - NEW YORK, U.S.A. - 22,23 Jan 2025

KINGPINS SHOW - HONG KONG - 21-22 NOV 2024

KINGPINS SHOW - AMSTERDAM - 23-24 OCT 2024

MAGIC - LAS VEGAS - 19-21 AUG 2024

KINGPINS SHOW - NEW YORK, U.S.A. - 17,18 JULY 2024

Denims and Jeans Vietnam - HO CHI MINH, VIETNAM - 26,27 JUNE 2024

PV DENIM - MILANO - 5,6 June 2024

BANGLADESH DENIM EXPO - BANGLADESH - 6,7MAY 2024

KINGPINS SHOW - AMSTERDAM - 24-25 APRIL 2024

DENIMS AND JEANS - TOKYO - 26-27MARCH 2024

PV PARIS - PARIS - 6-8 Feb 2024

KINGPINS SHOW - NEW YORK, U.S.A. - 24,25 JANUARY 2024

XDD TEXTILE COMPANY LIMITED